Real Time Conveyor Diagnostic System Model M411-106-10K

Description

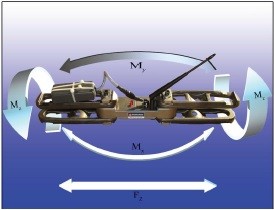

The patented M411-106-10K conveyor diagnostic system consists of a multiple axes sensor with on-board amplifiers, ADCs for each measurement axis, on-board 915 MHz transmitter with antenna, and remotely located base station transceiver with antenna. The base station is connected to the USB port of a user supplied PC. When properly installed in a belt conveyor the M411-106-10K system measures, while the conveyor is in motion, tensile force Fz, horizontal bending moment Mx, vertical bending moment My, and twisting moment Mz. The M411-106-10K is supplied with software to help the user acquire and display the measured data in real time and archive the measured data for later comparison and analysis. The M411-106-10K is the ideal analytical tool to help anticipate and prevent costly conveyor breakdowns, and as an evaluation tool to help establish benchmarks for newly installed, or repaired, conveyors.