FREQUENCY RESPONSE:

The Key Specification that's often overlooked

One may wonder if this discussion has anything to do at all with force and /or torque sensors, however with little patience, not only some ambiguity will be removed, but also some very decisive eye-openers will be revealed when considering a sensor for an application.

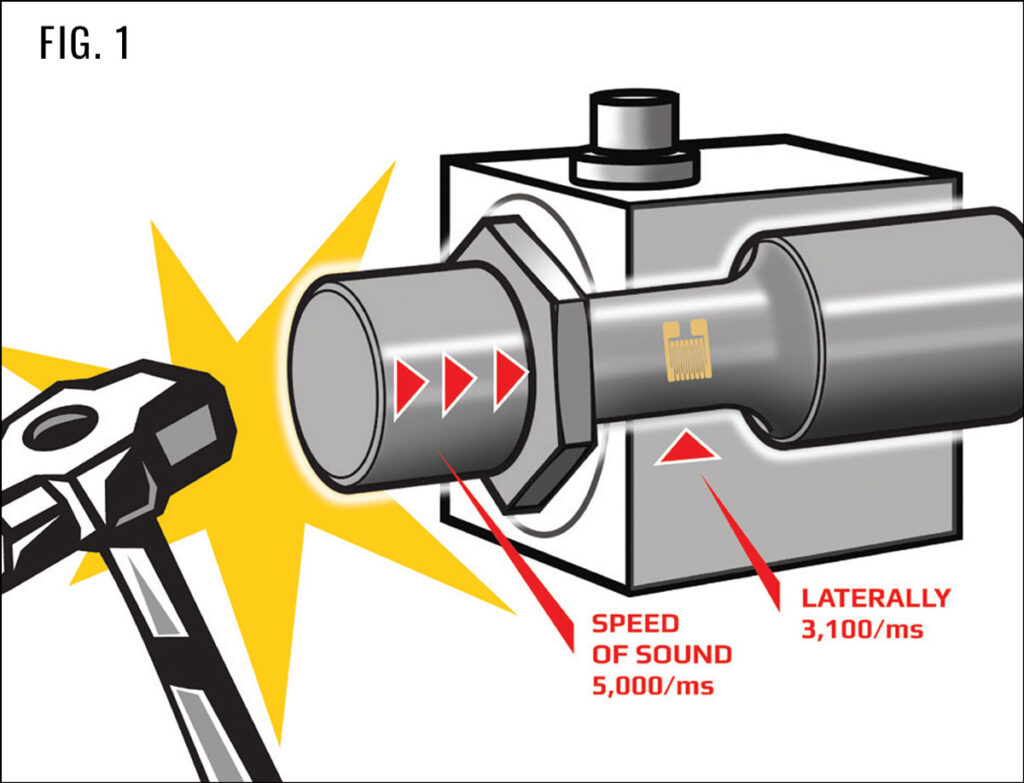

The schematic (FIG. 1) is a simplified yet very accurate representation to what happens in a sensor, from the moment an event (e.g. impact force) is applied to the sensor till this event shows up on an indicator.

The event (the impact) causes a stress wave that travels in the sensor at the speed of sound longitudinally (at 5000 m/s) and laterally (at 3100 m/s) to reach strain gauge locations.

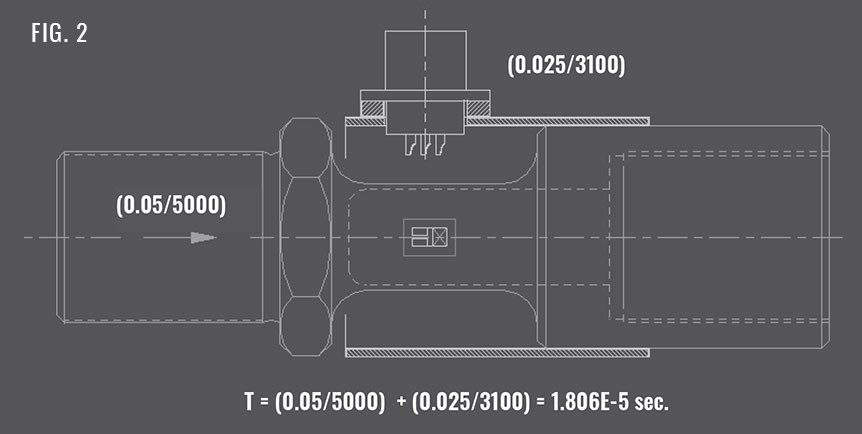

Assuming a sensor 10cm long, and 5cm diameter, gauges are in the middle of the sensor, then time “T” for stress wave (event) to reach gauges;

T=(0.05/5000) + (0.025/3200) = 1.806E-5 sec. (FIG 2)

i.e. this sensor can respond to a signal frequency 1/T = 55,357 Hz

For all practical purposes, any simple sensor (a Wheatstone bridge of strain gauges on a piece of metal) can translate the mechanical energy of an event into proportional electrical energy in almost no time

NEED A QUOTE?

We love helping our clients excel. We are happy to discuss your sensor requirements and provide ideas on how you can become more competitive, productive and profitable with SDT products.

This Month's SPECIALS

MODEL i100

Strain Gage Bridge Simulator

Our popular i100 hand held simulator generates precise mV/V signals to help develop, “troubleshoot,” and calibrate strain gage signal conditioners, instruments, signal processors, and data loggers.

Accuracy is ± 0.03%, temperature effects are 6 ppm/F, and zero balance is 0.0004 mV/V. Resistance of the i100 simulator is equivalent to a 350-ohm bridge. The i100 has 8 switch selectable output steps. Also, a Vernier knob is provided to allow the user to continuously adjust the output from –2 to + 2 mV/V. A convenient switch provides true reverse polarity. Connection to the i100 is made through either a PT style connector or 4 color-coded spring-loaded test clips. All critical internal contacts are gold plated. The i100 is compatible with AC carrier or DC strain gage signal conditioner electronics.

GIVE US YOUR FEEDBACK

We always are interested in your feedback to ensure that our site and our customer experience is the best it can be. Please let us know what you think.